Industrial control systems are rarely ever identical. That means customization and specific configuration is necessary, not to mention the alterations that take place over time as equipment is replaced or processes and parameters change. In addition, change management solutions can provide rapid recovery in the event of a disaster, increase security against unauthorized changes, either internal or external, and assist development teams working at the same time.

Organizations often use rudimentary spreadsheets or logbooks to document modifications, if at all. Our increasingly digital world has raised awareness about the risk of misconfiguration and the requirement for programmatic methods of tracking change across industrial systems. Thankfully, there are tools available specifically designed for tracking these changes and providing a common central repository for team usage.

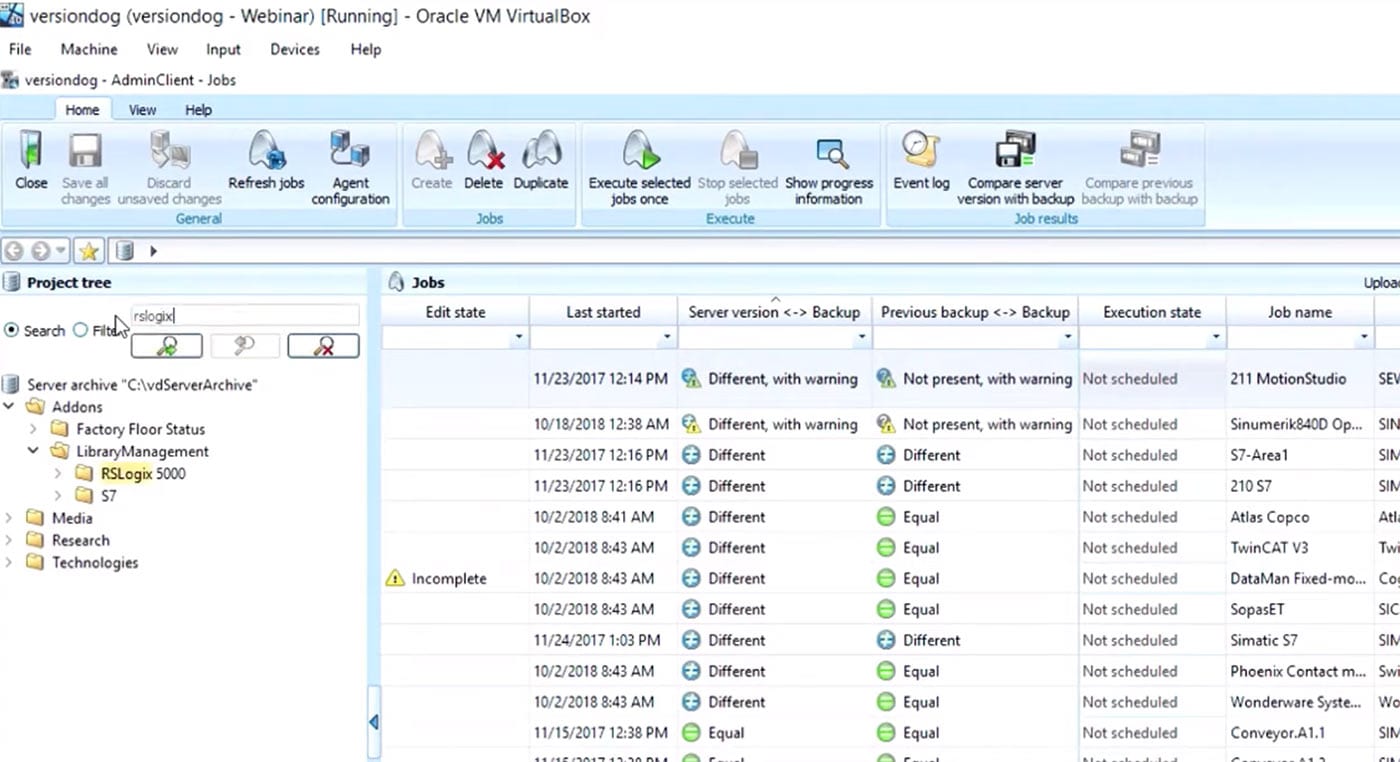

AUVESY versiondog

Provides greater control, security and visibility into understanding the who, what, when, where and why of changes to the automation device and system programming running across the plant floor.

AVEVA Control Configuration Manager

World’s first universal configuration solution that automates and standardizes programming and control across all operational technologies within an enterprise, regardless of type or vendor brand.

AVEVA Integration Studio

A cloud hosted development environment that facilitates greater collaboration, rapid project creation, project archival, scalability on-demand, and the ability to manage multiple AVEVA development projects simultaneously.