New ways of work adopted by chemical companies after the pandemic

Written by Fernanda Martins, Global Marketing Manager, AVEVA

The nature of work is changing, and this is not new. The difference today is that the rate of change is much higher, and it has been aggravated with the recent global pandemic. Chemical companies were heavily affected by the pandemic, being impacted by the oil crisis from one side and by drastic changes in consumer behavior from the other side. While different types of businesses were looking exclusively for enabling remote working during the lockdowns, chemical companies had to enable remote working and transform work and processes simultaneously. They needed to increase agility and resilience to respond to the new market demands quickly. According to Microsoft, two years of digital transformation were implemented in only two months due to the pandemic. With all these changes, we see the rising of a new generation of workers, digitally connected to become problem solvers who consciously add value to the business.

Eastman Chemicals

Eastman had developed a digital transformation program within its worldwide engineering and construction organization called SEIGA (Seamless EPCom Integrated Global Access). SEIGA provides Eastman engineers instant single-point access to integrated, accurate, reliable, and secure data, combined with automated workflow processes. This approach ensures that different disciplines work collaboratively, always using the same data and context, reducing errors and re-work. It increases efficiency during the project and construction phases and results in a reliable digital package to be handed over later to operations.

SCG Chemicals

SCG Chemicals achieved 100% plant reliability with a single platform that provides the workforce with a better understanding of operations performance. The Digital Reliability Platform (DRP) uses big data, AI, machine learning, and predictive analytics in the cloud to provide integrated, real-time visibility of data and KPIs empowering the workforce to make better decisions and increase operational efficiency. A trusted, real-time data blended with analytics enables team to predict equipment health, monitor performance, and drive optimizations more readily. The operational digital twin supports SCG Chemicals’ aim to drive zero unplanned downtime.

Total

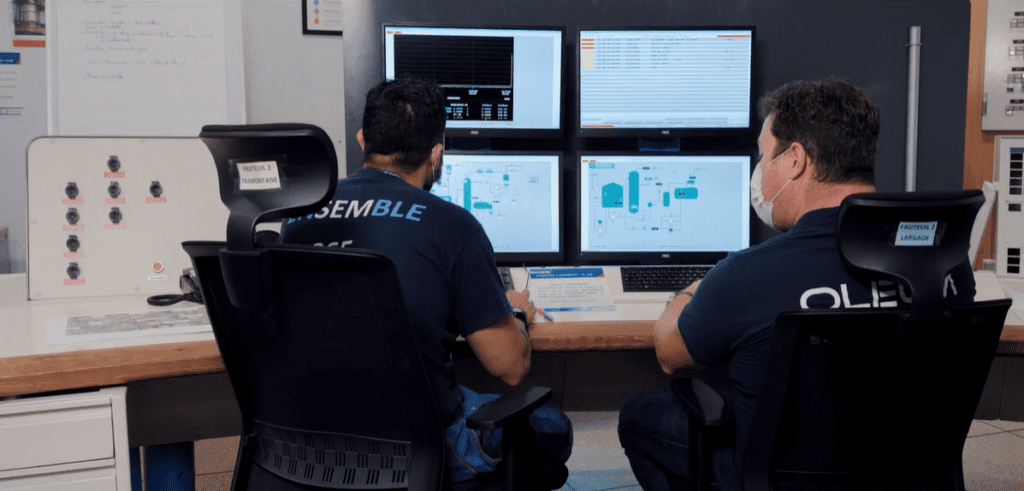

Total could ensure training during the pandemic through a realistic simulated operator training environment deployed in the cloud. The operator training simulator enables teams to learn how to handle any potential hazard situations. With easy access, training managers can create a wide range of exercises, adaptable for all trainee profiles fulfilling different training needs. The cloud-based solution provides access to the training from anywhere and at any time. With enhanced accessibility and scale, up to 2000 operators can be trained each year.

Dérivés Résiniques et Terpeniques (DRT)

DRT increased 15% in productivity by providing connectivity to the workforce and streamlining and optimizing processes. They completely digitalized several functions and developed digital tools on a unified platform to support production engineering, quality control, supply chain management, and upper management. By connecting these teams, they achieved improved process efficiency, better asset monitoring and maintenance, better product quality and genealogy control, real-time monitoring of resource consumption, energy costs control, identification of areas for optimization, fast and reliable reporting, and increased safety.